What is Electron Beam Welding?

Due to the extreme density and precise controls of the electrons, high weld “depth to width” ratios can be achieved, up to 20-1 is obtainable. With minimal or no distortion, Electron Beam welding is often the final step of a production sequence.

Why use Electron Beam Welding?

Why use Electron Beam Welding?

Electron Beam welding can offer advantages such as lower heat input, minimal heat-affected zone, and no part distortion. These attributes make it ideal for the welding of intricate final assembly products or sensors that have delicate instrumentation close to the weld joint.

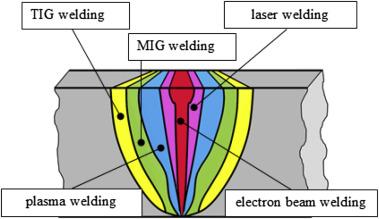

Electron Beam Weld Profile

The comparison of an EB Weld versus conventional TIG/MIG welding illustrates

Electron Beam Welding can also save money by reducing joint preparation costs and repeatable settings reduce the risk of operator error.